The Quantifiable Impact of Using the Right Machining Tool

The Quantifiable Impact of Using the Right Machining Tool

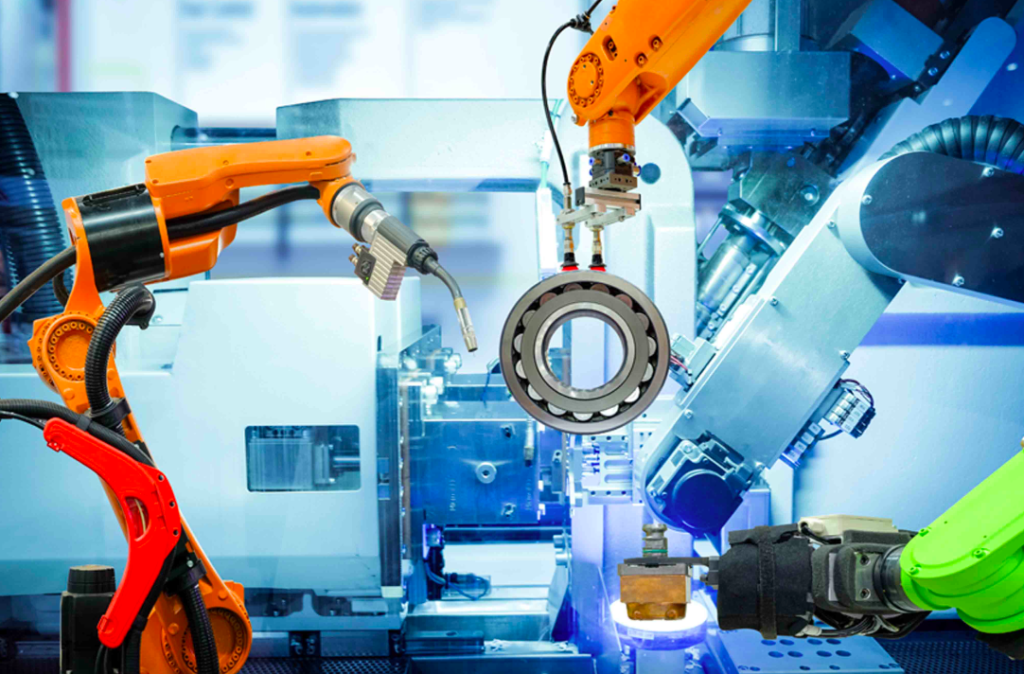

In the world of manufacturing and machining, the choice of tools can make a significant difference in outcomes. The impact of using the right machining tool cannot be overstated, as it directly influences efficiency, productivity, and overall quality. Let’s delve into the quantitative aspects of this impact to understand why selecting the appropriate tool is crucial for success.

What is sourcing?

Production Speed and Throughput: One of the most apparent benefits of using the right machining tool is the increase in production speed and throughput. A tool that matches the material, cutting requirements, and machine capabilities can significantly reduce cycle times. This translates into higher output levels within the same timeframe, boosting overall productivity.

Quality Metrics: Precision and accuracy are paramount in machining processes. The right tool ensures dimensional accuracy, surface finish, and part consistency. Quantifiable metrics such as tolerances achieved, surface roughness values, and scrap/rework rates can demonstrate the direct impact of using the appropriate tool on product quality.

Tool Life and Maintenance Costs: Choosing the right tool not only enhances performance but also extends tool life. Tools that are matched correctly to the application experience less wear and tear, reducing downtime for tool changes and associated maintenance. Calculating the cost per part based on tool longevity and maintenance requirements reveals the financial benefits of optimal tool selection.

Energy Efficiency: Using the right tool can also contribute to energy efficiency. Tools that cut more efficiently, generate less heat, and require lower cutting forces can result in reduced energy consumption per part produced. Energy usage metrics can quantify these savings, contributing to sustainability goals.

Overall Equipment Effectiveness (OEE): OEE is a comprehensive metric that combines availability, performance, and quality to assess equipment productivity. By using the right machining tool, each aspect of OEE can see improvements, leading to higher overall equipment effectiveness scores and better utilization of manufacturing assets.

conclusion

In conclusion, the impact of using the right machining tool is measurable across various quantitative parameters. From increased production speed and quality improvements to cost savings and enhanced equipment efficiency, making informed tool choices is a strategic decision with tangible benefits for manufacturing operations.